Description

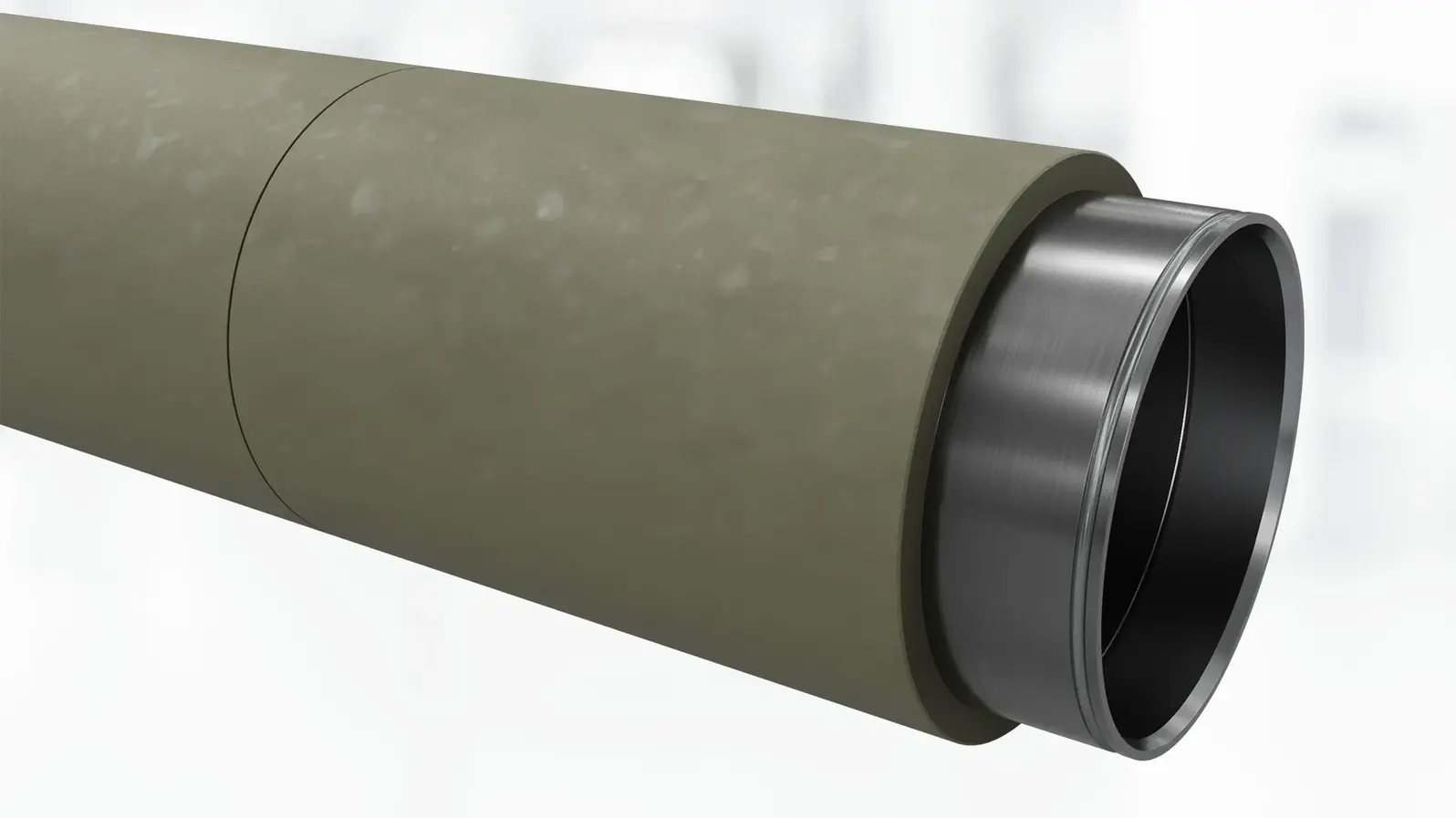

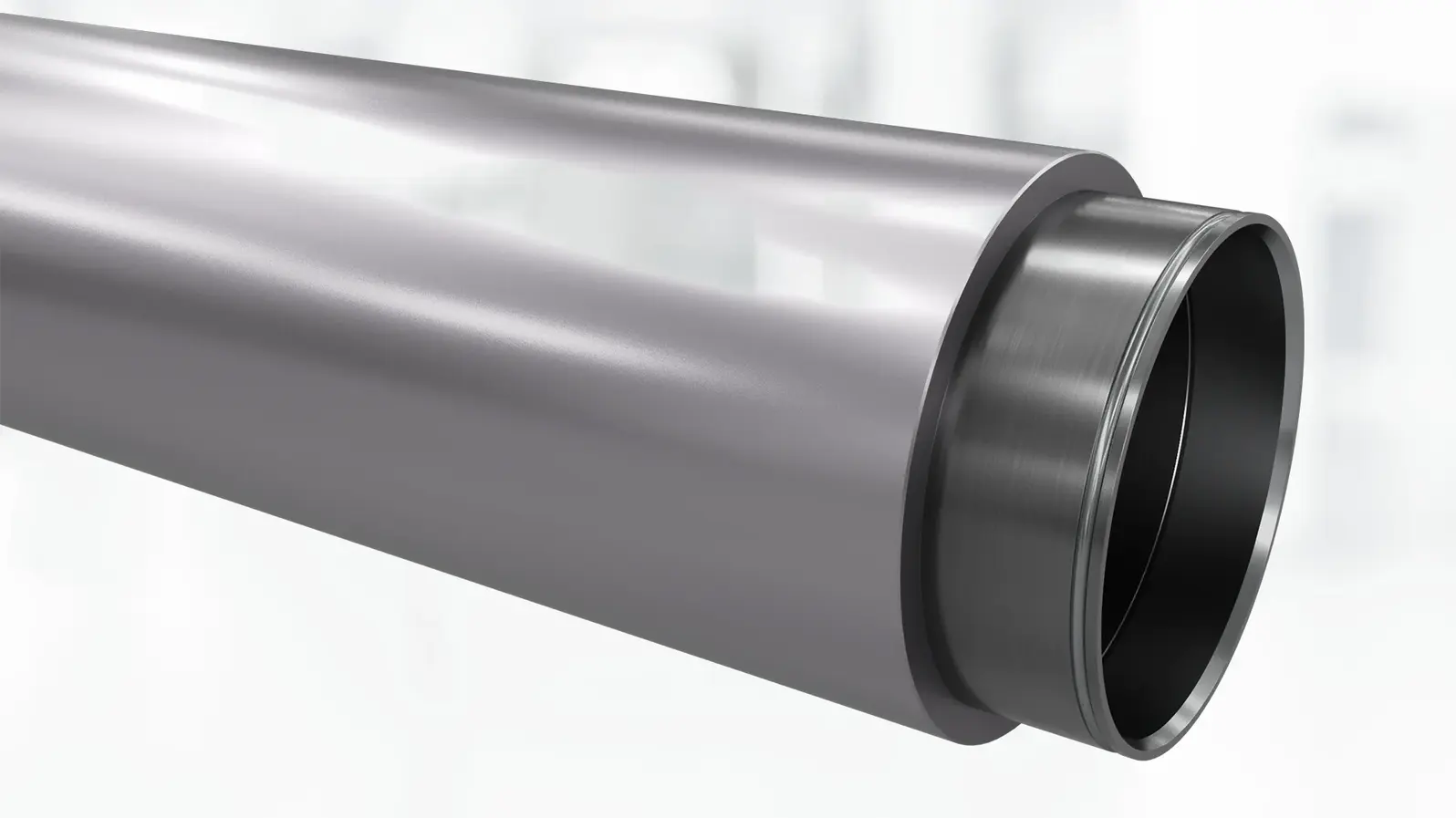

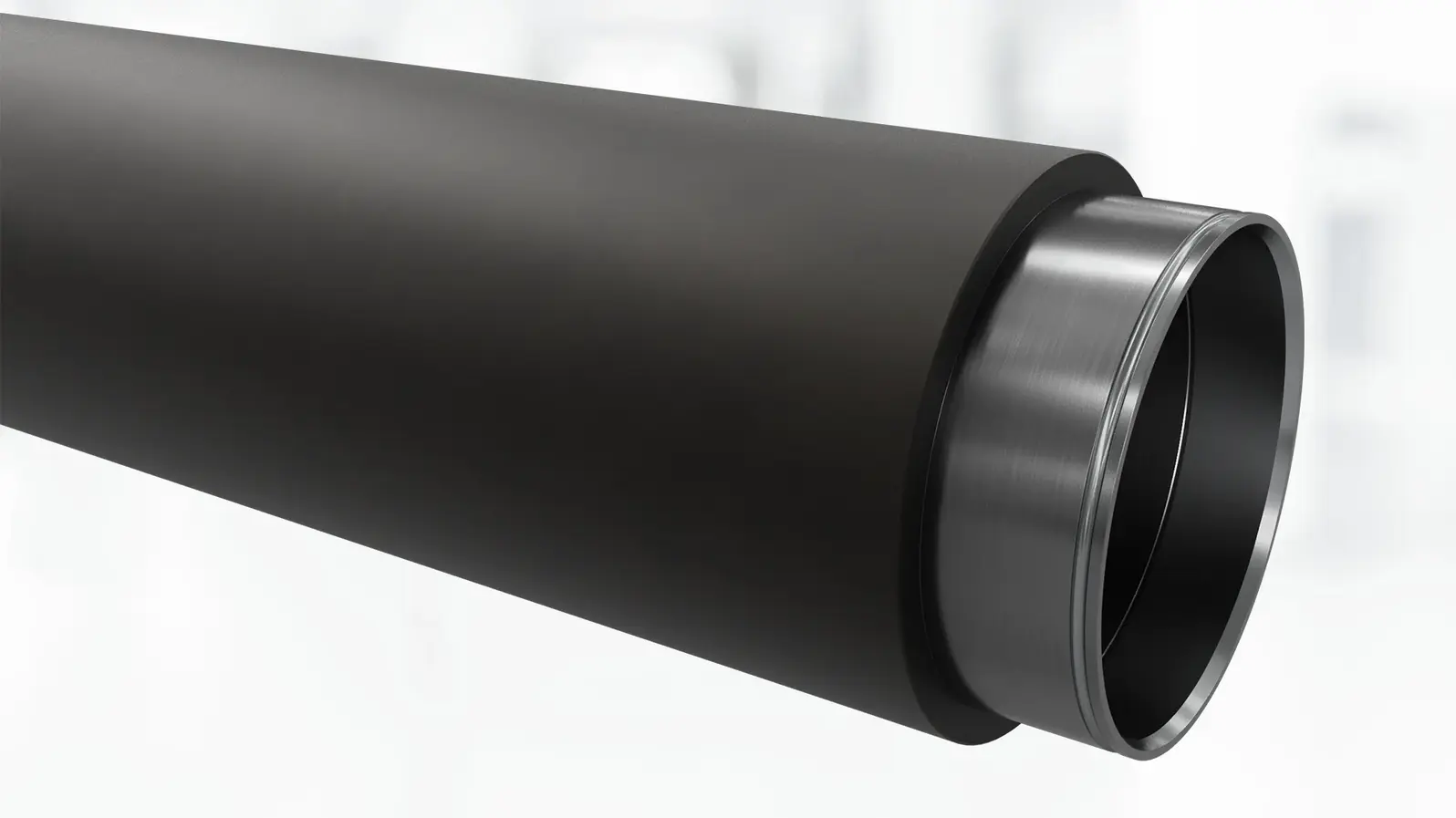

Rotatable targets are specially shaped sputtering targets that are manufactured as cylindrical or tubular bodies. In contrast to classic planar targets, they enable large-area, uniform coating, especially with rotating cathode systems. The external geometry is precisely adapted to the requirements of the respective coating systems.

Form

Cylindrical or tubular

Uniform wall thickness (straight) or larger outer diameter at the ends (dogbone)

Available as monolithic, sprayed or bonded materials (e.g. metals or ceramics)

Typical dimensions: customizable depending on the system and application

High material utilization

By rotating the target during the sputtering process, the target material is used more efficiently than with planar targets.

Homogeneous layer thickness

The rotation improves the homogeneity of the deposited layers on the substrate.

Longer service life

Reduced time for target change and longer operating cycles increase productivity.

Large coating areas

Ideal for industrial high-volume and flat glass coating

Flexible choice of material

Available in metals, alloys, oxides, nitrides and other composite materials

Architectural Glass & Automotive Glass

Architectural Glass, Automotive Glass, Solar Glass, Displays, Smart Glass

Electronics & Semiconductors

Optoelectronics, Advanced Packaging, Power Electronics, Photonics

Photovoltaics

Thin-Film Photovoltaics (z. B. CIGS, CdTe)